MCE18 stands for “Multifunction Can Bus Extension” with previously 18 connections (now 19) – why is this module needed?

Our displays ( MFD15 , MFD28 , MFD32 , MFD32S ) have four analog inputs. However, for some applications this may be too little and more inputs are required.

It makes sense to map this using the flexible Can Bus protocol. For this purpose, the sensors are connected to our MCE18 and sent via Can Bus to the device to be received – for example one of our displays.

But even freely programmable control devices only have a limited number of inputs. This can be easily expanded with our module and sent directly to the control unit.

9 analog inputs (0-5V)

8 digital inputs (on/off)

3 digital outputs (on/off LOW SIDE 0.5A) (new in v2!)

Tested with:

CANchecked MFD28/MFD32/MFD32S

MaxxECU

Ecumaster

LinkECU

Haltech (emulates an IO Extender A+B or just B)

Syvecs (coming soon)

Motec (coming soon)

aim

This device is also available without a housing: CFE18 – can switch board

– hardware –

Scope of delivery:

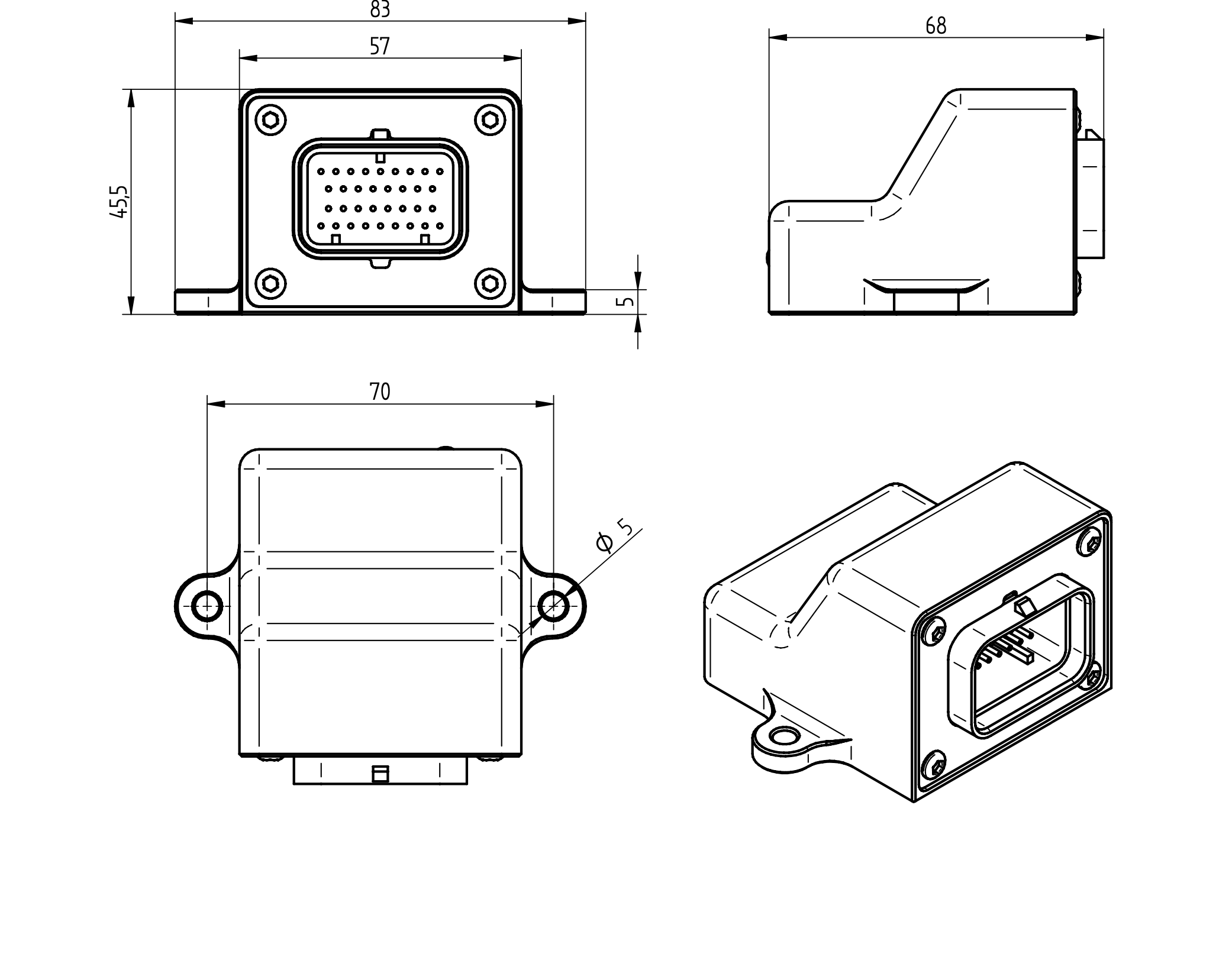

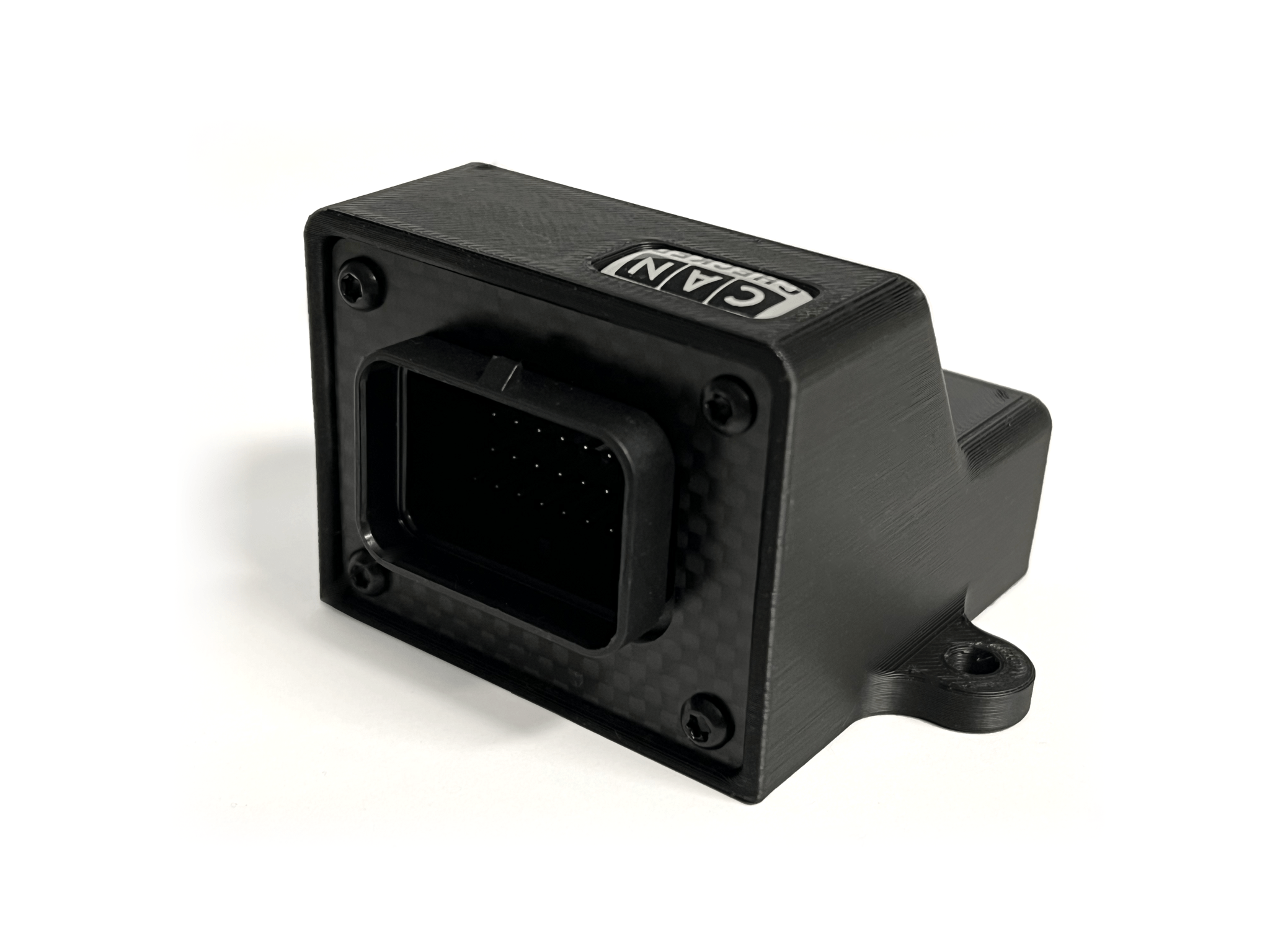

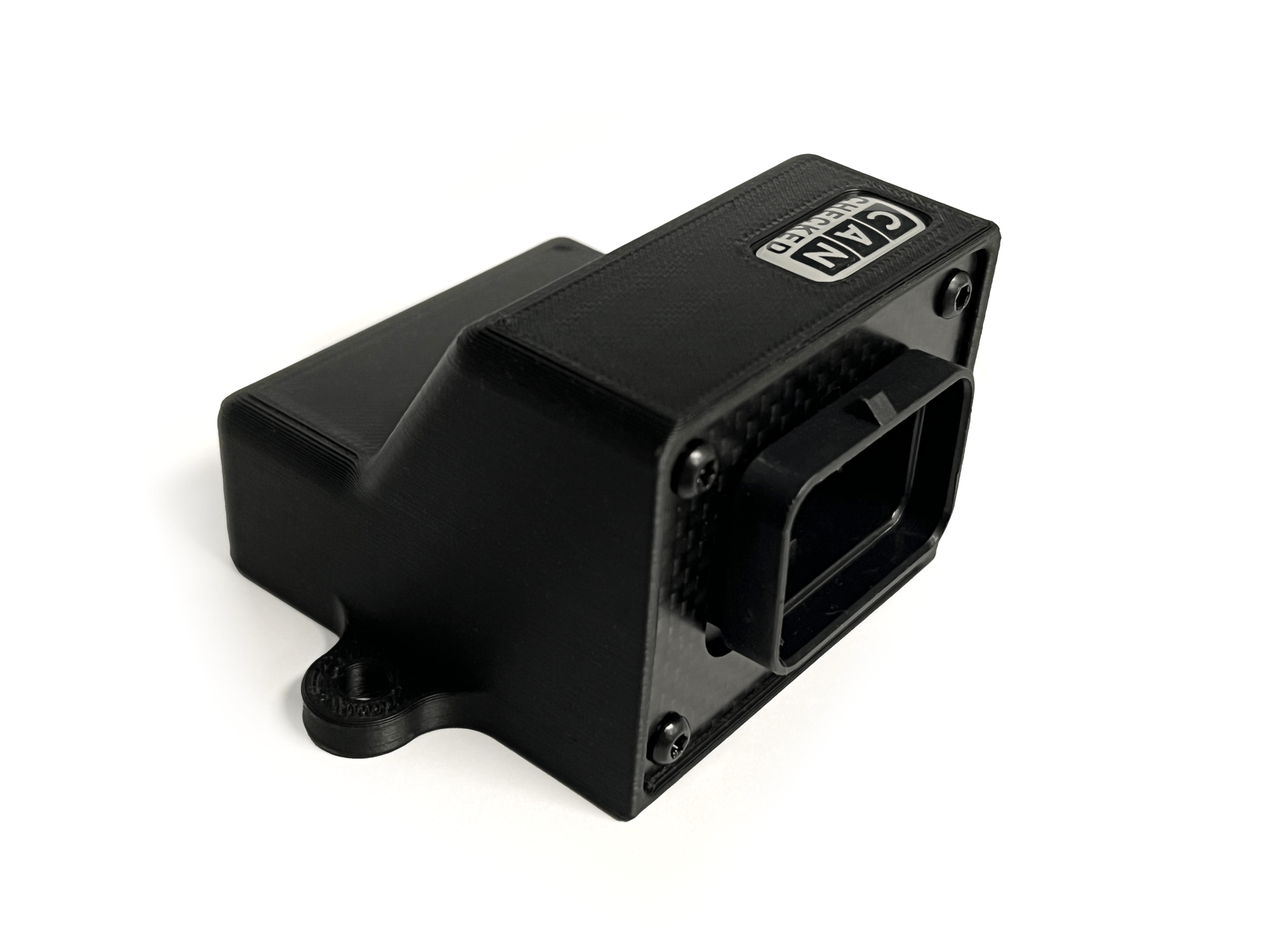

- MCE18 with case

- Connector Superseal 34pin (TE 4-1437290-0)

- Pins Superseal 1.0 20AWG (TE 3-1447221-4)

- 3 jumpers

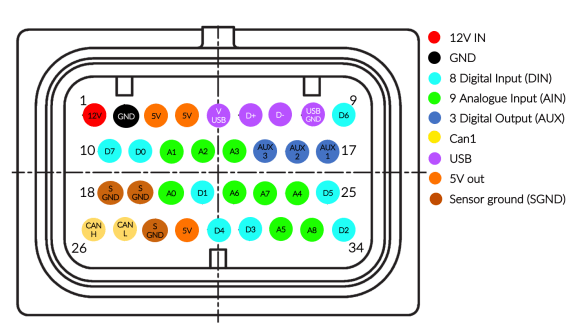

– pin assignment –

| Pin code | Designation | Description |

| 1 | +12V | 12V power supply |

| 2 | GND | Ground power supply |

| 3 | +5V | 5V sensor power supply |

| 4 | +5V | 5V sensor power supply |

| 5 | VBUS | 5V USB (usually red) |

| 6 | D+ | D+ USB data (mostly green) |

| 7 | D | D- USB data (mostly white) |

| 8th | USBGND | USB ground (usually black) |

| 9 | D6 | Digital input 6 |

| 10 | D7 | Digital input 7 (unused in v2 – board v0.8) |

| 11 | D0 | Digital input 0 |

| 12 | A1 | Analog input 1 |

| 13 | A2 | Analog input 2 |

| 14 | A3 | Analog input 3 |

| 15 | AUX3 | Digital output 3 |

| 16 | AUX2 | Digital output 2 |

| 17 | AUX1 | Digital output 1 |

| 18 | SGND | sensor mass |

| 19 | SGND | sensor mass |

| 20 | A0 | Analog input 0 |

| 21 | D1 | Digital input 1 |

| 22 | A6 | Analog input 6 |

| 23 | A7 | Analog input 7 |

| 24 | A4 | Analog input 4 |

| 25 | D5 | Digital input 5 |

| 26 | CANH | Can Bus High |

| 27 | CANL | Can Bus Low |

| 28 | SGND | sensor mass |

| 29 | +5V | 5V sensor power supply |

| 30 | D4 | Digital input 4 |

| 31 | D3 | Digital input 3 |

| 32 | A5 | Analog input 5 |

| 33 | A8 | Analog input 8 |

| 34 | D2 | Digital input 2 |

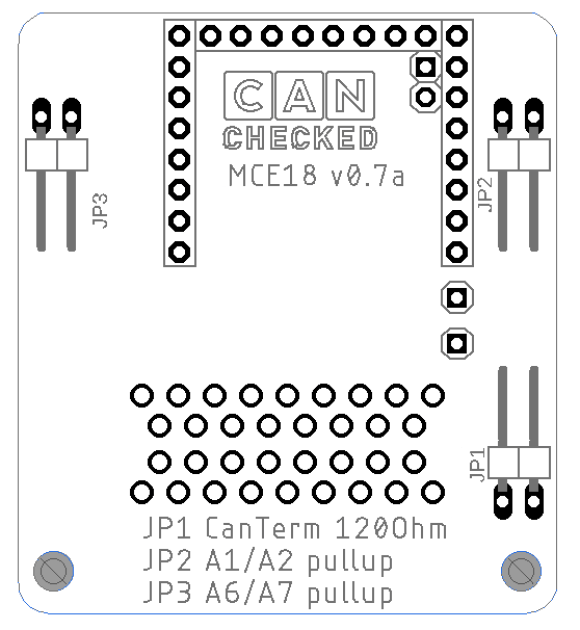

– Jumper configuration –

If you remove the front 4 screws, you can pull off the housing. There are three jumpers on the back.

1) JP1 inserted activates the 120 ohm resistor for the Can Bus

2) JP2 inserted activates the 1K1 pullup resistor for A1 and A2

3) JP3 inserted activates the 1K1 pullup resistor for A6 and A7

By default, all jumpers are removed

– Default CAN Bus Stream –

The input data is queried and transmitted every 50ms (20Hz – changeable). The data is transmitted as “unsigned big endian”.

As soon as 12V and ground are connected, the green status LED on the back lights up.

Can Bus ID: 0x700 ( Base Data CAN ID – changeable)

| byte | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Base ID | AIN0 0-1023 | AIN1 0-1023 | AIN2 0-1023 | AIN3 0-1023 | ||||

| Base ID +1 | AIN4 0-1023 | AIN5 0-1023 | AIN6 0-1023 | AIN7 0-1023 | ||||

| Base ID +2 | AIN8 0-1023 | bit masked DIN0-6 | bit masked AUX1-4 | N/A | N/A | device chip temperature | Version=4 | |

MCE18 TRI File Download MCE18/CFE18 Tri File

MCE18 DBC File Download MCE18/CFE18 DBC File

The configuration or modification of the Can Stream is described in CFE18 – Can Bus Function Extension .

– Digital outputs –

The MCE18 has three digital outputs in the v2. These can be loaded up to a maximum of 500mA and switch to ground (LOW SIDE).

To do this, you send a Can Bus frame every 100ms (CAN Id can be configured here – if there is a 500ms pause between the frames, the timeout is activated and the outputs are deactivated): (

0=inactive, 1=active)

| byte | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| CAN RX ID (default: 0x640) | AUX1 0/1 | AUX2 0/1 | AUX3 0/1 | unused | ||||

The setting is made via Can Bus – see CFE18 => ” Configuration options “

– AIN smoothing –

If the analog inputs fluctuate too much, they can be smoothed out using software. This can be configured separately for each analog input.

The higher the smoothing, the quieter (smoother) the value becomes, but it also reacts more slowly to fluctuations. Here you have to find a healthy middle ground.

Values go from 0-249 – the higher the more smoothing, 0= no smoothing, default: 160

The setting is made via Can Bus – see CFE18 => ” Configuration options “

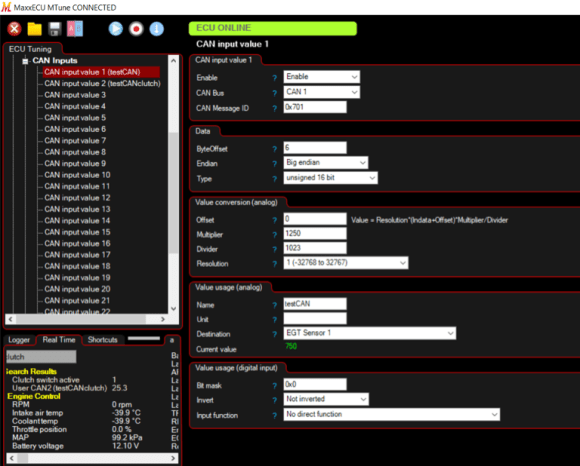

– Control unit / ECU configuration –

The analog inputs provide 10-bit resolution and therefore values from 0 to 1023. The value must be converted in the control unit. All values are “unsigned big endian”

Examples:

5V voltage AIN0

0x700 Byte0+1

Multiplier: 5; divisor: 1023; Offset: 0

or multiplier: 0.004887585533

Exhaust gas temperature (type k) AIN7:

0x702 Byte6+7

Multiplier: 1250; divisor: 1023; Offset: 0

or multiplier: 1.2218963832

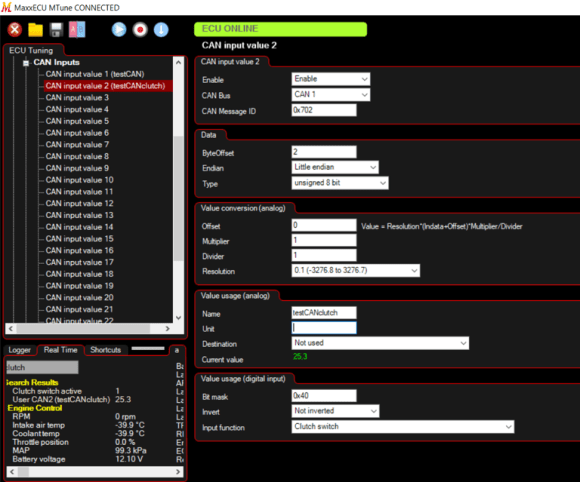

Either the individual bytes are used for the digital inputs. Eg DIN6: 0x702 byte 6 or the bit mask at 0x702 byte2

e.g. DIN6: 0x702 Byte2 Mask:0x40

Here is a little cheat sheet to do the calculations for a MaxxECU: maxxecu-sensor-calculation.xlsx

– Documentation / Download –

MCE18 TRI File Download MCE18/CFE18 Tri File

MCE18 DBC File Download MCE18/CFE18 DBC File

MCE18 MaxxECU File Download MCE18/CFE18 MaxxECU File